This article's professional tool repair instructions will show you how to replace an engine's ignition switch, a common cause of small engine failure.

Gas-powered lawn & garden tools can fail to start-up for many reasons. Spark plugs, carburetors, pull cords, flywheels, filters, and fuel lines are just some of the parts that contribute to proper engine start-up.

A malfunctioning ignition coil is a common reason for why a gas-powered engine might not fire up right away (or at all). Ignition coil modules must be replaced when they go out.

Using a two-cycle line trimmer as an example, and this How-to article will show you how to replace an ignition coil in a gas-powered engine. In addition, we'll offer some advice for diagnosing potential ignition coil failure on practically any gas-powered engine.

Many tool repairs can be performed right at home, saving you the time and money that would otherwise go to a repair shop. Even repairs that require some dismantling and specific steps can be a cakewalk for tool users equipped with the right know-how.

Ignition Coil Function and Diagnosis

Ignition coil modules rest closely to an engine's flywheel. Flywheels have a magnet on them that passes the ignition coil module as the flywheel spins.

The passing flywheel magnet generates an electric charge inside the ignition coil module, and the module transfers that charge to the engine's spark plug. It's easy to see why a healthy ignition coil is necessary for an engine to start and run at all.

In addition, the mechanism inside the ignition module is set on a timing sequence that coordinates with the speed of the turning flywheel's passing magnet. Sometimes an ignition coil will fail simply by being out of sync with the timing of the flywheel.

A mistimed ignition coil may not fail completely. In other words, the engine may still run, but run poorly.

In any case, testing an engine's ignition coil is a smart diagnosing step if your gas-powered tool isn't starting or if it is running irradicably.

It might be a good idea to eliminate other possibilities first, such as carburetor problems, clogged filters, bad spark plugs, and fuel lines.

Testing an ignition coil requires a special diagnosing tool called a spark tester. Spark testers are inexpensive and easy to use.

Here are the steps for using a spark tester to diagnose an ignition coil:

Remove the Engine's Spark Plugbook.

Attach the Boot End of your Spark Tester to the Engines Spark Plug.

Insert the Other End of the Spark Tester into your Engine's Spark Plug Boot.

Pull the Engine's Starter Rope.

The spark tester breaks (and then completes) the circuit from the ignition coil to the spark plug. Once the spark tester is positioned correctly and securely,give your engine's start cord a few pulls.

If the ignition coil is working properly, then the window on the spark tester will light up with electrical charge when you pull the start cord. If the spark tester window does not light up when you pull the start cord, then you can be sure that your ignition coil needs to be replaced.

Replacing an ignition coil requires a little dismantling and is a more invasive engine repair than average, so it's best not to just guess when it comes to replacing your coil.

Spark testers can be found and purchased at most hardware stores.

Ignition Coil Replacement Steps

We replace the ignition coil on a Shindaiwa T242 EPA2 Gas Trimmer for this demonstration.

Getting the right ignition coil for your machine is truly the first step for this repair. Use your tool's model number in our "Search By Model Number" field at the top of the page to navigate to your machine's parts list and breakdown diagram.

View this Shindaiwa trimmer's ignition coil page by clicking here.

Here are the steps for replacing this trimmer's ignition coil. The following steps will be very similar for all gas engine makes and models:

#1 Disassemble the Trimmer

Most (or all) of an engine's housings and shrouds should be removed to perform this repair. A driver for your tool's fastening system (torx, phillips, hex, etc.) is the only tool you need for this step.

1. Remove the spark plug boot.

2. Remove the air filter housing.

3. Remove all other trimmer engine shrouds.

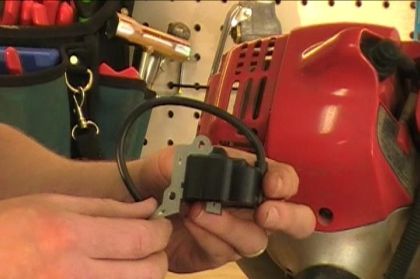

#2 Remove the Old Ignition Coil Module

The ignition coil will be attached to your engine in three ways: with fasteners holding the module to the engine, ignition wires connecting to the engine, and at the spark plug boot.

You'll need a couple pairs of needle nose pliers and a screwdriver for these steps:

1. Using two pairs of needle nose pliers, disconnect the ignition wires from the engine.

2. Make sure the spark plug boot is disconnected.

2. Make sure the spark plug boot is disconnected.

3. Unscrew the fasteners holding the old ignition coil to the tool's engine.

Your old ignition coil is now freed up and can be removed.

Your old ignition coil is now freed up and can be removed.

#3 Transfer Module Components to New Module

Your new ignition module will most likely be missing a couple of small components. Don't worry; components from the old module are meant to be transferred to the new module.

Four parts must be transferred from the old ignition coil: the spark plug boot, the spark plug coil spring, the ignition wire protective heat shield, and the ignition wire itself. Sounds complicated maybe, but it's actually very easy. Make sure to assemble the components on the new module in reverse order that you removed them from the old module.

Here are the steps:

1. Pull the spark plug boot off the old module.

2. Remove the spark plug coil spring from the old module.

The end of the spark plug coil spring will have two wires set at 90º angles. The wire ends actually puncture the insulation of the spark plug wire. You will have to pull these ends out of the wire.

3. Remove the ignition wire heat shield from the old module.

This should just slide right off.

4. Using a pair of needle nose pliers, pull the ignition wire out of the old module.

Transfer the module parts to the new module by assembling them in reverse order that you disassembled them from the old module.

5. Install the ignition wire in the new module using needle nose pliers.

6. Slide the protective heat shield over the module wires on the new ignition coil.

7. Install the spark plug coil spring on the new module's spark plug wire.

You will need a pair of needle nose pliers for this step as well. Use the pliers to press the angled ends of the coil into the insulation of the spark plug wire.

Both wires on the coil should be firmly punctured through the insulation in the center of the wire, positioned so that the coil rests at the end of the spark plug wire.

Both wires on the coil should be firmly punctured through the insulation in the center of the wire, positioned so that the coil rests at the end of the spark plug wire.

8. Press the spark plug boot back onto the coil spring.

The new ignition module is not ready for installation into your gas engine.

#4 Install the New Ignition Coil

You will reinstall your new ignition coil by reattaching it in the same three ways it was attached to the engine to begin with. This is pretty simple, but there's one important detail that can not be overlooked.

The ignition coil is designed to be a very specific distance from the flywheel. This is because the magnetism of the passing magnet on the flywheel must be distanced just right to produce an electrical charge in the ignition coil module.

You have a couple options for spacing the module the correct distance from the flywheel:

- Use a spacer card. Most manufacturers provide spacer cards for these kinds of repairs like the one pictured below. If you have an official spacer card available, it's the best option for this step.

- If you don't have a manufacturer spacer card, a thick business card can serve as a substitute.

1. Turn the flywheel until the magnet is facing the direction of the ignition module.

1. Turn the flywheel until the magnet is facing the direction of the ignition module.

2. Prepare the module for reinstallation.

Simply insert the module's fasteners by hand into their original positions before installing the coil.

3. Set the spacer card down on the magnet.

4. Refasten the module to the engine.

Do not completely fasten the module at this point. You'll want a little play left in it so you can make one last double check on its spacing before fully tightening.

5. Reconnect the ignition wires to the engine.

6. Double check spacing and fully tighten the module.

Make sure that the module is resting (not pressed) on the spacer gauge as you fully tighten the fasteners.

7. After the module is fully tightened on the engine, remove the spacer card.

The magnetism of the flywheel magnet will automatically adjust spacing of the module into position even further as the machine operates.

#5 Reassemble the Trimmer

Again, reassembly will logically follow reverse order of disassembly.

1. Reinstall shrouds and housings.

2. Replace the air filter housing.

3. Replace the spark plug boot on the engine's spark plug.

You're new ignition coil is now completely installed, and your gas powered machine is ready for operation!

Admittedly, this repair has quite a few individual steps, but believe it or not, you can replace a an ignition module in your power tool in under 15 minutes, and at a fraction of the cost of your power tool.

Conclusion

If your gas powered machine or power tools is having a hard time running and starting, make sure not to overlook your engine's ignition coil as a possible cause.

Visit our Engine Parts Page to get started on your ignition coil repair. You can search by category for your tool's make and model, or you can simply enter your model in the search field at the top of this page.

With these professional repair tips, you're on your way to increasing the value of your equipment again and again.

We strongly recommend that you view this How To article's video demonstration before beginning your repair:

Comments

No Comments Exist

Be the first, drop a comment!